Senior engineering major John Albers spent months working with three other students from Engineers for a Sustainable World, a campus club that he is president of, developing a tool to dry breadfruit, a nutritional crop found in tropical regions, for the Peace Engineering: Breadfruit Drier Contest.

However, Albers‘ group, made up of St. Thomas juniors Andrew Kasper, Eric Ruudand and Paul Cordes, found out in early February that the months of hard work did not pay off. A group from Compatible Technology International (CTI) submitted the winning design.

“My team didn’t win, so we aren’t working on it anymore,” Albers said. “(We) worked on it on and off from October to December, then we found out it was going to be a contest… so we worked a lot harder.”

Mechanical Engineering Program Director Camille George, who works in association with CTI to make food-processing technology for developing countries, contacted Albers in October with the project proposal.

“She wanted to get this thing off the ground… this idea of harvesting an under-utilized nutritional resource,” Albers said.

After starting on the project in the fall, ESW began to lag behind schedule. George decided to make the design a competition by giving teams from across the nation a chance to compete for prizes. The first-place design received $3,000 and two tickets to Hawaii to present the designs to the National Tropical Botanical Garden, which sponsored the competition.

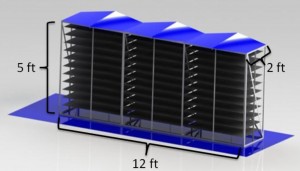

The primary goal of the project was to develop a drying system that would be completely independent of external need (materials and service) and could be used to produce an exportable product, Albers said.

The final design will be tested in Jamaica and Haiti for feisability.

“That gives you an idea of… how important this project could be to those countries,” Albers said.

Processing the food is a four-part process, to better preserve the nutrients the fruit has to offer. The competition was to design the tool for the second stage of the process: drying.

The process consisted of: collecting the ripened breadfruit, which spoil within 48 hours of falling off the tree and slicing it into strips using a grinder. The fruit is then moved onto a drying rack (the tool ESW was working on) to dry by wind and sun “sitting out in the open like wet clothes,” Albers said.

After the fruit dries, it can be ground into nutritious flour that can be stored much longer than the fruit.

Freshman Ashley Bruber said that she likes that the university encourages clubs to take part in these types of projects.

“I think it is important to give back, and I think St. Thomas is a great school for clubs like that,” Bruber said.

Patrick Roche can be reached at roch6667@stthomas.edu